Mellow steel, moreover known as low-carbon steel, maybe a flexible and broadly utilized fabric in different businesses due to its favorable adjustment of quality, ductility, and cost-effectiveness. To know what is mild steel characterized by its moo carbon substance, more often than not extending 0.25%, which gives a few interesting properties to the steel. To improve its execution for particular applications, mellow steel experiences a few handling and treatment procedures. This article investigates these strategies in detail, centering on how they progress the material's mechanical and physical properties.

Improving Mellow Steel Execution: Handling and Treatment Strategies

Gentle steel, known for its moo carbon substance and flexibility, benefits altogether from different handling and treatment procedures to optimize its execution. Key strategies incorporate essential preparation through BOS or EAF, warm medicines like toughening and normalizing, and surface medicines such as galvanizing and portraying. Alloying with components like manganese and silicon encourages tailors its properties. Mechanical handling, counting rolling, and producing, refine the steel shape and strength. Thorough quality control guarantees that the ultimate item meets the required benchmarks for strength and execution.

Fundamental Preparing of Gentle Steel

The primary handling of gentle steel starts with its generation through the essential oxygen steelmaking (BOS) or electric circular segment heater (EAF) strategies. Within the BOS preparation, liquid press from an impact heater is refined by blowing oxygen through it, which decreases the carbon substance and removes impurities. The EAF strategy includes dissolving scrap steel and alloying components utilizing an electric bend, which is at that point refined to realize the specified composition. The steel is at that point cast into different shapes such as billets, blossoms, or chunks, which are in this way hot-rolled or cold-rolled into last products like plates, sheets, and bars. The essential processing guarantees that mellow steel accomplishes a uniform structure and composition appropriate for encouraging treatment.

Warm Treatment Techniques

Heat treatment could be a vital step in upgrading the execution of mellow steel. The foremost common warm treatments include annealing, normalizing, and extinguishing. Strengthening includes warming the steel to a particular temperature and after that cooling it gradually, which diminishes inside stresses and improves ductility and durability. Normalizing, on the other hand, includes warming the steel to a temperature over its basic point and after that air-cooling it. This handle refines the grain structure, upgrades mechanical properties, and moves forward machinability. Whereas extinguishing isn't regularly utilized for gentle steel due to its potential to extend hardness past alluring levels, it is once in a while utilized in combination with hardening to realize particular mechanical properties.

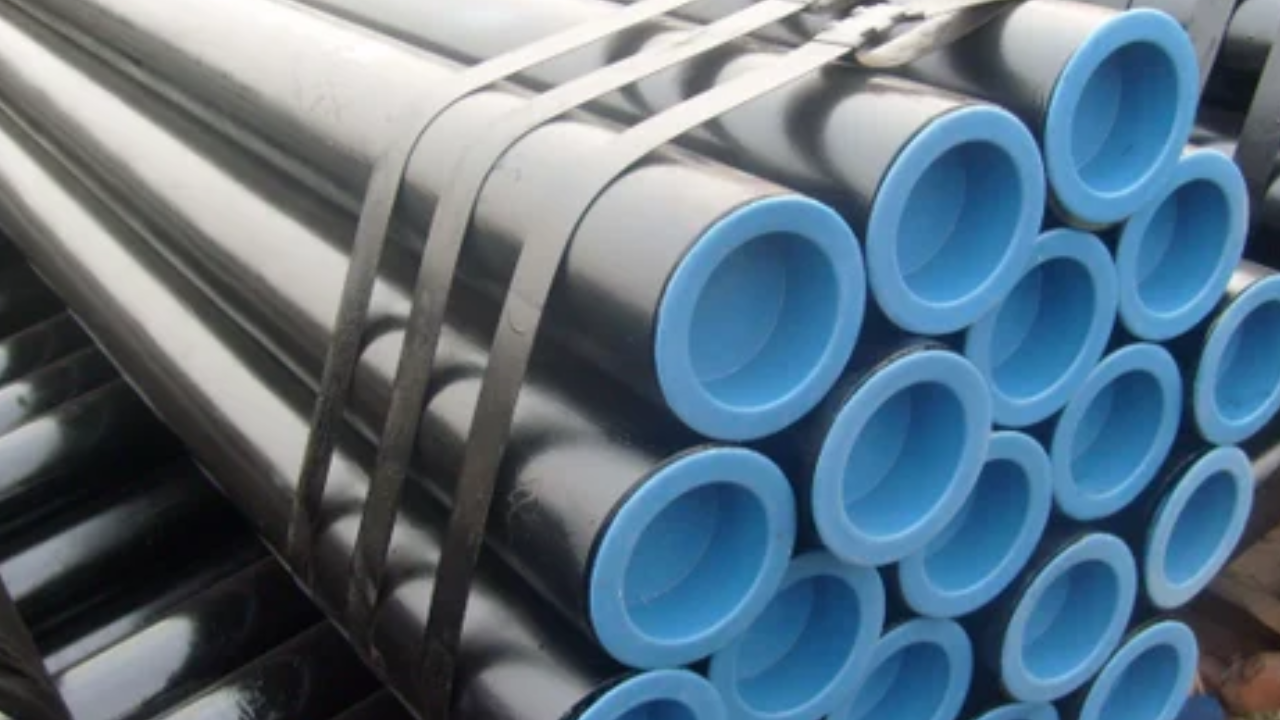

Surface Medications and Coatings

Surface medicines and coatings are utilized to move forward the strength and erosion resistance of mellow steel. One common surface treatment is galvanizing, where the steel is coated with a layer of zinc to protect it from rust and natural debasement. Another treatment is phosphating, which includes applying a phosphate coating that upgrades erosion resistance and gives a great surface for portraying or encouraging coating. Also, portray and powder coating are utilized to supply an additional layer of assurance and stylish offer. These coatings not as it were extend the lifespan of mellow steel items but also progress their execution in different natural conditions.

Alloying and Added substance Components

Even though mellow steel is comprised of press and a small sum of carbon, its properties can be encouraged to improve by including alloying components. Common added substances incorporate manganese, which moves forward quality and hardness, and silicon, which increments ductile quality and diminishes defenselessness to rust. Other components like chromium and molybdenum can moreover be included in little sums to upgrade particular properties such as resistance to wear and high-temperature quality. By carefully controlling the composition and extent of these added substances, producers can tailor the mellow steel to meet the prerequisites of diverse applications.

Mechanical Handling Strategies

Mechanical handling strategies such as rolling, fashioning, and machining are basic for forming and wrapping up gentle steel items. Hot rolling includes passing the steel through rollers at tall temperatures to attain wanted shapes and measurements. This process also makes a difference in refining the grain structure and moving forward mechanical properties. Fashioning, which includes forming the steel utilizing compressive strengths, upgrades its quality and durability by adjusting the grain structure. Machining processes like turning, processing, and penetrating are employed to realize precise dimensions and surface wraps. These mechanical forms guarantee that mellow steel items meet the specified details and execution benchmarks.

Quality Control and Testing

Quality control and testing are integral to ensuring that gentle steel items meet the specified execution criteria. Different tests are conducted to evaluate the mechanical properties, such as pliable quality, abdicate quality, and impact resistance. Non-destructive testing strategies, counting ultrasonic testing and radiographic inspection, are utilized to identify inner imperfections and guarantee basic judgment.

Conclusion

Gentle steel's flexibility and favorable properties make it a profitable fabric for various businesses. By utilizing different preparation and treatment techniques, such as warm treatment, surface coating, alloying, mechanical handling, and rigid quality control, producers can altogether improve their performance to meet particular application prerequisites. Each handling step plays a crucial part in refining the steel's properties, making strides in its toughness, quality, and resistance to environmental variables. Understanding these strategies not as it were highlights the flexibility of gentle steel but moreover underscores the significance of exact designing in optimizing fabric execution for assorted applications.